-

-

Water soluble laundry bag for infection control in hospitals

-

0.000.00

-

2003 mass laundry staffs infected SARS in Taiwan Peace Hospital, one died from SARS infection, the hospital was sentenced to compensate 7.48 million yuan. After the incident, hospitals around the world have introduced laundry processed Textiles biocontamination control system, which pushed the overall system control points to higher requirements (including textiles collection, transportation, sorting, washing, drying, folding and transportation).

For the infection prevention system of hospitals, infection control for the contaminated textile play an important role. Medical textiles control system is a systematic project in which disinfection and washing only contribute small parts of the system. Textile collection, classification, transportation, storage, delivery and uses are also important for the infection control of hospital personnel and the system management. To deal with those contaminated textiles, first and foremost task is to prevent infection of personnel and the environment, then reduce the costs and cost savings. For the existing problems of the current textile laundry sysyem, using the application of water soluble laundry bag for textile collection is an ideal and effective way of infection control.

Performance of water soluble laundry bag for infection control

| 1. | Avoid contaminated medical waste to be generated as the disposal bags completely dissolve in water (water temperature adjustable), eliminating the traditional treatment by incineration or burying, and reducing the relevant treatment costs; |

| 2. | Water soluble laundry bag is effective in isolation of contaminated articles. The bags are kept sealed during the whole process from used textile collection, disinfection and washing. These greatly reduce the risk of contamination and cross-infection among the staff in hospital; |

| 3. | The application of water soluble laundry bags improve and simplify the working environment by reducing the process packages opening for classification and transferring into washing machines, reducing the labor cost and the risk hurting by the sharps articles which may be left in the textiles, conducive to health care of the operators In addition, the risk of huge compensation for cross-infections will be reduced greatly caused by the; |

| 4. | The application of water soluble laundry bags reduces the cost of operators,protection and anti-infection, and their insurance expenses. |

| 5. | The new biodegradable material, water soluble laundry bag, do not cause environmental and water pollution as it is non-toxic and fully biodegradable. |

Relevant regulations apply in the water soluble laundry bag

1) Meet the guidelines of U.S. Centers for Disease Control and Prevention(CDC)

2) Comply with regulations of U.S. Occupational Safety and Health Administration (OSHA)

3) Meet the guidelines of Healthcare Laundry Accreditation Council (HLAC)

4) Comply with European Standard EN 14065:2002 Textiles-Laundry processed textiles-Bio-contamination Control System

5) Meet the guidelines of NHS Hospital laundry arrangements for used and infected linen

6) Meet the Regulation of China Sterilization Standard for Medical Organization

7) Meet the Infection Control Management Regulation in Hospital

Usage of water Soluble laundry bag

Specifications of water soluble laundry bag

Water soluble laundry bags comprise of water soluble materials with difference dissolved temperatures.

Fluid fabric collection bag (packaging with blood, body fluids contaminated fabrics)

Contaminated fabric collection bag (with contamination, pollution or infectious fabrics)

Common type fabric collection bag

| type | specification(mm) | model | Washing temp.(℃) | packing | colour |

| Type-W | 660×750 660×950 660×840 710×990 914×990 | Standard duty / heavy duty | ≥5 | 25 pcs / roll, 25 pcs / PE pack 100 pcs / case 200 pcs / case | Natrual / red / yellow / blue |

| Type-M | 660×750 660×950 660×840 710×990 914×990 | Standard duty / heavy duty | ≥5 | 25 pcs / roll, 25 pcs / PE pack 100 pcs / case 200 pcs / case | Natrual / red / yellow / blue |

| Type-H | 660×750 660×950 660×840 710×990 914×990 | Standard duty / heavy duty | ≥5 | 25 pcs / roll, 25 pcs / PE pack 100 pcs / case 200 pcs / case | Natrual / red / yellow / blue |

| Type-S | 660×750 660×950 660×840 710×990 914×990 | 20/25 | ≥5 | 25 pcs / roll, 25 pcs / PE pack 100 pcs / case 200 pcs / case | Natrual / red / yellow / blue |

*The above temperatures are the best recommended dissolving temperatures;

* Each bag is equipped with a cold water soluble colored tie.

*Color and specification are available upon the request of the clients.

WATER SOLUBLE LAUNDRY BAG OPERATING INSTRUCTION

IN STORAGE

| 1. | Keep bags sealed with protective overwrap until use. |

| 2. | Once a bag is removed from the pack, keep the remaining bags in overwrap material to prevent from moisture exposure. |

| 3. | Store overwrapped water soluble laundry bags at 7℃(45°F) to 30℃(86°F) and in Rh 20 to 70% moisture level for optimum shelf life. |

AT SETUP AND IN USE

| 1. | Handle the bag with dry hand only. Avoid any contact with moisture to preserve the film’s strength and integrity. |

| 2. | IMPORTANT: A linen item known to be dry should be the first item placed in the bag and it will form a dry foundation at the bottom. This provides a significant moisture isolation measure to the bag as the moist items are later placed in such bag. |

| 3. | Do not place overly wet items in the bag at any time. Remember the bag is sensitive to moisture in any form. |

AT CLOSURE

| 1. | Expel as much excess air as possible before closing bag. Avoid expelling the excess air to face. Reduction of trapped air content makes the closed bag a stronger and smaller unit for transshipment. |

| 2. | A colored neck tie is provided with every bag. Use it to close the bag. |

| 3. | Caution: Do not knot the bag film too many times as this will inhibit the solubility of the film during laundering. |

| 4. | The closed water soluble laundry bag should be placed within another outer bag (sack or PE bag) during the transfer. This reduces the chance of secondary contamination. |

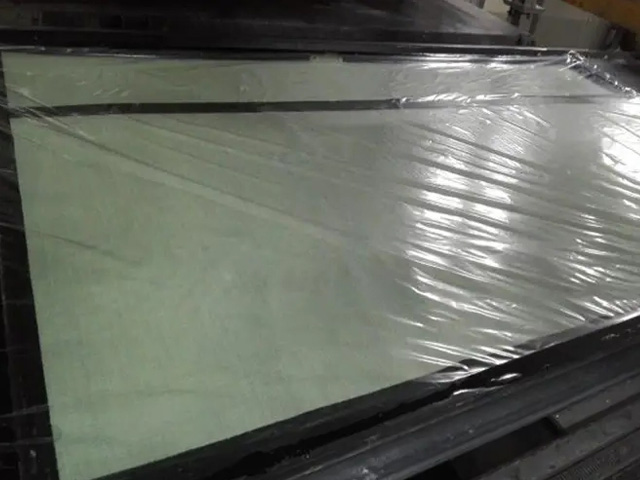

IN THE LAUNDRY

| 1. | The closed water soluble bag should be placed in the wash wheel or tunnel. Pre-sorting is contraindicated because the soiled linen is assumed to be contaminated. |

| 2. | During the initial cold flush cycle, whatever cold water soluble or hot water soluble type, the bag will open automatically and begin to disintegrate, allowing contact with the linen by the wash water. |

| 3. | For complete liquefaction of the film we urge the following: A. Do not overload the washer beyond its rated capacity. B. Be sure the water temperature reaches the recommended dissolving temperatures during the wash cycle C. The water should have been swirling around the bag linens for 40 seconds before the wash chemicals (detergent, alkali, etc.) are injected. The entire washing process lasts for at least 20 minutes. |